[ad_1]

The Tōhoku earthquake of 2011 remains the StrongestIt is the most significant event in Japanese history. It caused a tsunami that shook the world. over 40 metres dismantled coastal flood defencesWith ease, around 16,000 people have their lives saved in north-eastern Japan

Japanese authorities decided to build larger defenses in order to better protect their communities in the future. Concrete walls that extend over 400km and reach almost the limit of their height are constructed using concrete walls. 15 metres highIn order to resist the tsunami, the coast is now lined up in several places. Residents will have enough time to evacuate in the event that another tsunami strikes.

They were recently tested after a 7.4 magnitude earthquake struck off the Fukushima Prefecture’s coast on March 16, 2022. At least four people are killedThe tsunami also caused many injuries. The tsunami that resulted was much smaller than the one that occurred 11 years ago.

These sea walls will also act as a defensive line against the effects of climate changes. A recent report by the Intergovernmental Panel on Climate Change found that even in the best case, where the world halts warming at 1.5°C, sea levels could rise by 0.55 metresGlobally, the average is 2100. This could cause severe storm surges in many areas.

These walls, which are meant to protect people from the effects of global warming, also contribute to it. We estimated the emissions involved in creating north-eastern Japan’s concrete breakwaters at around six million tonnes of CO₂ by taking into account their size and length and using industry-standard tools.

Ravindra Jayaratne, Author provided

So how can countries build stronger shore walls without causing climate change to worsen? Following post-tsunami surveys of damaged breakwaters in southern Sri Lanka (2004) and north-eastern Japan (2011) with colleagues at Waseda University, and drawing from the University of East London’s low-carbon concrete research, we may have found an answer.

Low-carbon concrete

Concrete is the most popular material used to make breakwaters. Cement, the main binder in a concrete mix, is primarily made of clinker – a residue produced by firing limestone and clay in a furnace heated to 14,500°C. This heat is usually created by burning fossil fuels, which emits greenhouse gases.

Cement manufacturing is responsible for approximately 7% of annual CO₂ emissions. But without concrete, many of the world’s most impressive buildings and structures – such as Australia’s Sydney Opera House and the Hoover Dam in Las Vegas – wouldn’t exist. One of the biggest challenges facing the construction sector is reducing concrete’s carbon footprint while keeping the benefitsA durable and affordable building material.

You can achieve this by replacing cement with granulated iron slag from steelworks or pulverised ash of coal power plants (essentially, the leftover that can be scraped from the bottoms of furnaces).

Our newly designed low-carbon concrete mixesBoth of these materials can be used. It was possible to use as much as 60% of the steel furnace waste in the concrete mixes without it losing its compressive strength. This is critical for ensuring that the structure lasts. The mix had a 40% lower carbon footprint than traditional concrete.

Our designsSteel fibres, which are similar to hairpins, can be added into the concrete mix. This eliminates the need for large steel mesh grids. As a result, construction costs and emissions are lower and the final product is as strong as a traditional breakwater.

Working with the natural world

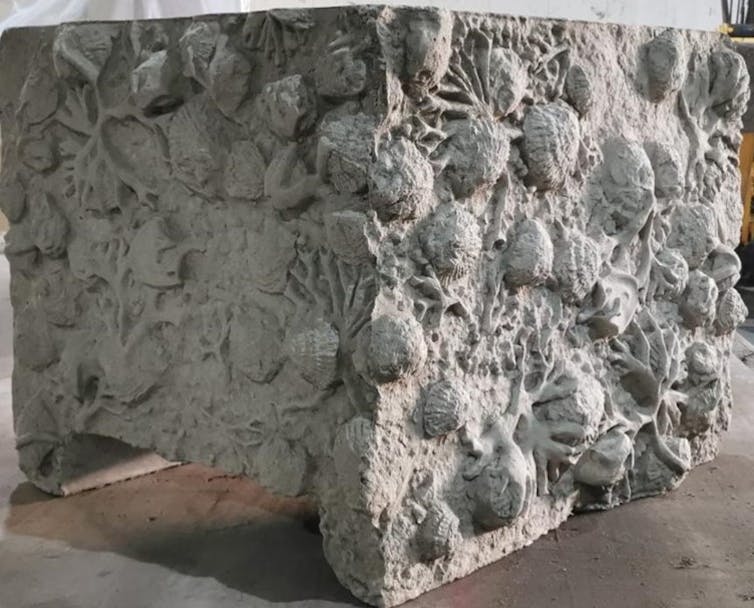

Concrete breakwaters are even possible Encourage biodiversity. Some are texture in such a manner that they Recreate reef habitats, encouraging the establishment and growth of marine animals and plants in their grooves or protruding surfaces.

Sensicon, Author provided

Even the best-designed breakwaters can crack over time. Amazingly, engineers have created self-healing concrete. Microorganisms capable to produce limestoneThese structures can be repaired autonomously by living organisms. It is exciting to imagine living organisms working through concrete and repairing it, a material that is usually considered dead and cold.

Future concrete designs will likely be more sustainable as 3D printing makes it possible to create more efficient patterns and less waste.

It is possible to worry about using less to build more coastal communitiesThese people live in fear of tsunamis and sustainable breakwaters will be thinner, smaller, and more curved than straight. These structures are still strong and demonstrate that the world can adapt to climate change without making it worse.

Don’t have time to read about climate change as much as you’d like?

Instead, get a weekly roundup delivered to your inbox. Every Wednesday, The Conversation’s environment editor writes Imagine, a short email that goes a little deeper into just one climate issue. Join the 10,000+ readers who’ve subscribed so far.