Our sponsors made this content possible. Click here to add content.

Dealers and builders realize that it is a great time to work together to combat rising labor costs and rising material prices as the COVID-19 pandemic enters its third year.

According to the National Association of Home Builders, (NAHB), Framing lumber pricesThe average single-family home cost rose $30,000 between 2020 and 2021. Everything, from garage doors to faucets, is backordered. In addition to the supply chain problems, finding labor can be a challenge. A US dealer claims that it has hundreds open positions, despite the fact that it is subject to material price swings.

A second NAHB study was done in partnership by Wells Fargo. It found that builder confidence fell as measured by the NAHB. Housing Market Index. According to the NAHB report, both higher material costs as well as labor shortages have contributed to the decline of builder confidence.

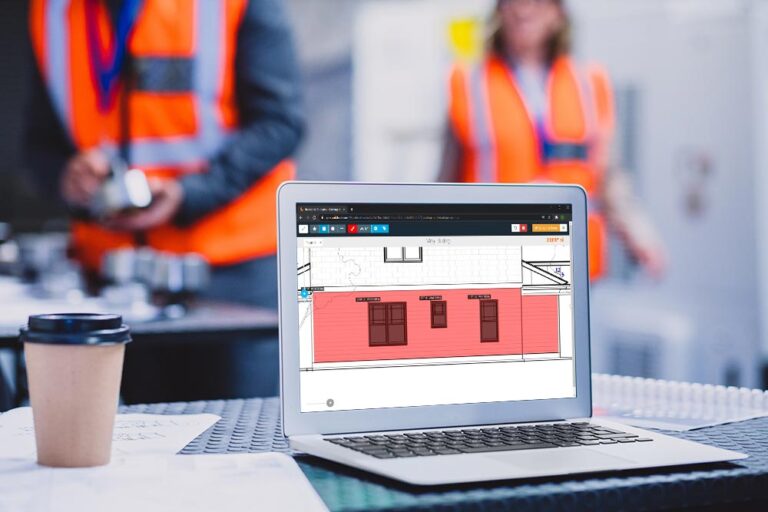

To counter the uncertainty, dealers are partnered with custom builders. SoftwareTo improve communication, consultation.

With material costs constantly changing, it is important that builders offer homeowners options. It is not ideal for homeowners to be able to choose their builder, but the current market requires that builders have multiple options in order to prevent projects from being delayed. Customers appreciate more price options and transparency from builders.

Pricing accuracy is possible with integrated price lists

Builders must be able to offer options. They must also provide accurate labor and material estimates that are clearly stated in a customer quote. Builders can use the right software to do this. Perform takeoffsYou can quickly generate estimates and quotes. Online digital tools eliminate human error associated with traditional takeoff methods. Recent innovations make it possible to offer builders the most current pricing whenever they need it.

For example:Epicor BisTrack and BuildxactThis software platform has extended the relationship between the builder and the dealer. This software platform allows dealers to offer builders the most current pricing at any hour of the day or night. Builders can then place orders directly into the dealer ERP.

The digitization of the pricing relationship between the dealer and builder eliminates manual pricing. This reduces the time spent returning multiple phone calls and emails. This reduces the possibility of errors creeping into orders when prices fluctuate. Inaccurate pricing can happen in just a few days on the current market. Incorrect pricing negatively impacts builders profit margins, as it is difficult for them to pass on unexpected price hikes to the homeowner.

Software still offers many benefits to builders and dealers. Dealer account managers who spend less on pricing find they have more free time to consult customers. In a more collaborative environment, builders are more likely to quote more work to prospects and win those jobs.

These transactions can be made simpler if the dealer uses integrated price list to create recipes. This involves grouping SKUs together to create packaged components. Door jams, hinges, locksets, and locks can all be used to create a door installation recipe. The builder can easily add all these items to the estimate in one click. Missing items can not only waste time but also cause unnecessary cost increases in current pricing environments.

Online software like Buildxact allows dealers to capture transactions from a wide range of customers. This data can be gathered to help dealers better understand the needs and wants of remodelers and builders. Dealers can look beyond the SKUs builders are purchasing to see which ones they aren’t. This transparency allows for better inventory planning and more productive conversations with builders about their buying decisions. Dealers may be able to win back sales they might lose to their competitors by doing this.

Software features that integrate seamlessly with job estimates and scheduling

When software integrates features such as those in Buildxact, it is possible to create highly accurate estimates. Builders can create simple schedules for subcontractors using takeoffs. To reduce miscommunication and contractor downtime, each contractor can receive reminders via email or text.

John McBride, a general contractor and real estate investor, says that accurate estimates and well-planned schedules can help contractors avoid leaving jobs.

McBride manages multiple projects at once and uses them to avoid unforeseen delays like bad weather from bringing a project to an abrupt halt. It prevents subcontractors from arriving at the wrong phase of a project due to scheduling conflicts. Builders run the risk of contractors not being available later in the project cycle if this happens. Skilled labor shortage.

McBride uses Buildxact for email and text messaging to inform subcontractors about changes in scheduling. This allows him to maximize the use of skilled labor.

McBride stated that the software makes it easier for me to communicate with all my subcontractors. It allows me to see the entire process from one place, which is essential to be able to pick alternate times slots in case someone is late and notify any other subcontractors.

Buildxact’s construction management software creates a record of all jobs so that builders are aware of the time required to complete each job. These records can be used for evaluation of subcontractor performance. This helps to control labor costs.

Buildxact is a great software solution for builders and dealers, as it offers many features. It allows for transparent communication, higher levels of collaboration, and keeps uncertainty to a minimum.

Construction projects can continue to move forward despite the turbulent times caused by the COVID-19 pandemic.