By Susha Cheriyedath, M.Sc.Jan 27, 2022Skyla Baily reviewed

By Susha Cheriyedath, M.Sc.Jan 27, 2022Skyla Baily reviewedIn an article that was recently published in the journal MaterialsResearchers experimentally demonstrated that high-viscosity bulkfill resins from the new generation of bulk-fill resins are more resistant than low-viscosity bulkfill resins to mechanical damage after artificial ageing and treatment with water or ethanol.

Study: Changes in the Mechanical Properties of the Bulk-Fill Composites New Generation – Aging-Dependent. Image Credit: megaflopp/Shutterstock.com

Background

Dental medicine uses bulk-fill resins a lot. It is very beneficial to use composite fillings correctly. This saves time and is extremely advantageous. They can be used in a thickness range of 4-5mm for simpler clinical procedures with no adverse effects.

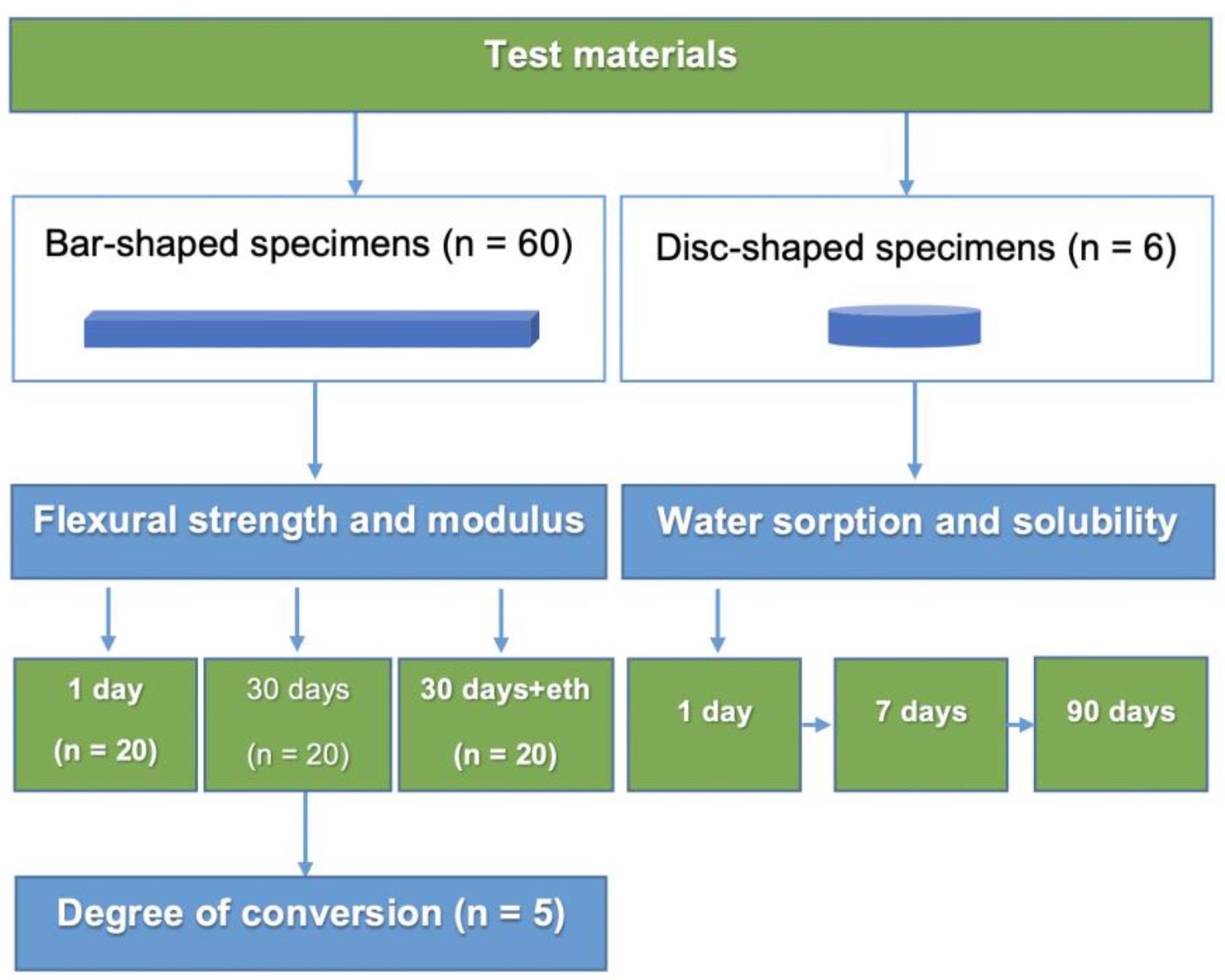

Flow diagram of the experiments. Image Credit: Danijela M et al., Materials

Numerous studies have been conducted to determine which bulk-fill resins are most effective in preventing dental treatment complications. Many studies focused on polymerization pathways that make dental procedures easy.

Bulk-fill composite resins have special photo-initiators like Bis- (4-methoxybenzoyl] diethyl germanium. It is also commercially known as Ivocerin. It is a Norrish I type photo-initiator based on germanium and is part of composites such as Tetric PowerFill (PFILL) and Tetric Power Flow (PFLW). Ivocerin decreases polymerization time, which reduces the age of bulk-fill composite resins. It also allows light penetration depths that are higher than camphorquinone. The Fill-Up! The Fill-Up! (COL), dual-cure bulk fill material contains, in the addition to camphorquinone and benzoyl Peroxide, which acts a chemical polymerization initiator.

This study evaluated the properties and chemical compositions of these materials in comparison to bulk-fill composites.

About the Study

Researchers evaluated the behavior and aging of bulk-fill resin composites in the presence of prolonged exposure to water and accelerated aging with ethanol in the current study. Six new-generation bulk-fill composite resins were tested: Filtek One Bulk Fill Restorative, PFILL, PFLW and SDR Plus Bulk Fill Flowable. They were compared to two reference materials, Tetric EvoFlow and Tetric EvoCeram.

A fourth-generation, poly wave LED curing device, with a Blue phase and Power Cure and Ivoclar Vivadent at high power mode, was used to induce polymerization in the investigated materials. The average value of 950 mW/cm was achieved.2. Before each sampling procedure, the radiant escapeance was measured three times using a handheld radiometer. The average was then calculated. The emission spectrum from the curing unit had a blue peak at 447 nm, and a violet peak of 404 nm.

To find the best material for long-term use, we used both disc- and bar-shaped materials. These materials were tested for flexural strength, flexural modulus, and solubility for a period 30 days. Water sorption was also tested for a period 90 days.

Also evaluated are the three-point bending stress and degree conversion parameters. Polished aluminum molds with a groove of size 16 × 2 ×2 mm3They were used to make the specimens. The strips of polyethylene covered the top and bottom apertures. On each side, light-curing took place six times, three times every 20 seconds, with a radiant exitance at 950 mW/cm2. To ensure that the light guide was in the correct position, a custom-made silicone mold was used. The specimens were kept in the dark in 4 mL saline solution at 37 °C in plastic containers with a conical bottom (10 samples each).

img alt=”Flexural modus (GPa), values of materials tested according to ISO 4049. Equal letters signify statistically homogeneous groupings for a specific time point. The statistically identical groups for each material are indicated by parentheses (p). < 0.05)." src="https://retime.org/wp-content/uploads/2022/01/1643297656_586_Bulk-Fill-Resin-Composites-Aqueous-Environment-Exposure.jpg" style="width: 2000px; height: 1166px;" width="2000" height="1166"/>

Materials tested according to ISO 4049 have a flexible modulus (GPa). Equal letters signify statistically homogeneous groupings for a specific time point. Parentheses indicate statistically similar groups for each material (p < 0.05). Image Credit: Danijela M et al., Materials

A two-way ANOVA was used in order to account for the factors “material”, and “depth”. Because both factors had a significant impact on the degree of conversion, one-way comparisons were made at the individual levels of each factor. To compare the degree of material conversion and to assess water sorption and solubility between materials, one-way ANOVA was used and Tukey’s post-hoc test was used. Independent observations t-tests were used for comparing the degree of conversion at depths between 0 and 2 mm within a particular material.

Observations

All five bulk-fill resins tested showed an increase of material reliability over time. These materials showed a shift in the distribution of flexural strength values, with COL and TBF showing higher values and COL showing lower values. After ethanol aging, PFILL, FIL and SDR showed an increase in material dependability, while TFLW showed a decrease.

All tested materials had a high conversion rate of over 80%. There were no statistically significant differences between the samples’ bottom and top. SDR was the least converted, while COL showed the highest conversion.

TEC showed transient reliability, which decreased after 30 consecutive days. Similarly, COL had the highest water sorption values exceeding 20 μg/mm3FIL was followed by TFLW, which had statistically similar results. PFLW has one of the lowest water absorption rates. TFLW, COL and FIL with the highest water absorption rates over 90 days are inconsistent with FIL or COL with the highest degree conversion. This is because lower water sorption is often associated with higher conversion.

TFLW and TEC had negative solubility, whereas PFILL had a very low solubility.

img alt=”Comparative water sorption and solubility testing materials. Uppercase letters indicate statistically comparable sorption values, and lowercase letters indicate statistically comparable solubility values (p). < 0.05)." src="https://retime.org/wp-content/uploads/2022/01/1643297657_490_Bulk-Fill-Resin-Composites-Aqueous-Environment-Exposure.jpg" style="width: 2000px; height: 1296px;" width="2000" height="1296"/>

Comparison of water solubility and sorption of tested materials. Uppercase letters indicate statistically similar sorption values, while lowercase letters indicate statistically similar solubility values (p < 0.05). Image Credit: Danijela M et al., Materials

Conclusions

This study revealed that high-viscosity bulkfill resin composites can withstand mechanical wear caused by aging. It has been shown that low-viscosity bulk-fill material is less resistant to artificial aging in ethanol and water. This means that they require a coated, high-viscosity top-layer.

The experimental conditions for the current study included an extended curing period, which was longer than the manufacturer’s recommended curing time, and a 2 mm depth. These conditions were material-dependent and the trends in mechanical characteristics following in vitro accelerated ageing were significant.

Filtek One Bulk-fill, a new generation bulk-fill composite incorporating addition–fragmentation chain transfer technology, had exceptional mechanical qualities and a high conversion rate despite significant water sorption. Tetric PowerFill, another material containing an addition–fragmentation chain transfer reagent, was significantly improved than its predecessor, Tetric EvoCeram Bulk-fill.

Source

Danijela Marovic, Matej Par, Matea Macan, Nikolina Klarić, Iva Plazonić, Zrinka Tarle Materials. Changes in the Mechanical Properties of Bulk-Fill Composites as they Age doi: https://www.mdpi.com/1996-1944/15/3/902

Disclaimer: These views are the author’s and do not necessarily reflect the views of AZoM.com Limited/A AZoNetwork. This disclaimer is part the Terms and Conditions of use of this site.