The use of renewable energy systems like solar panels, wind turbines and electric cars, This will reduce greenhouse gas emissionsIt will also help to reduce global warming. These systems require a lot more metal and must be used more often.

The World BankIt is estimated that around three billion tonnes of metals such as graphite, cobalt, and lithium will be required by 2050 to supply enough system to keep the global temperature rise under 2 C. This goal has been set by the United Nations. Paris Climate Agreement, 2016. To meet current renewable energy system usage, it would take only one billion tonnes of metals.

Since Canada has a lot of metals available.Can it become a global leader for the supply of materials necessary to create renewable energy systems?

It could, but the rise in the These metals are subject to environmental, energy, and water footprints.To meet the metal demand could negate any gains achieved by renewable energy systems.

(Shutterstock)

Sustainability vs. fossil fuel options

Some argue that it is impossible to combine these two goals.We have to make difficult decisions. The alternative is to adapt to global climate change.

This ignores a few important things, like the technological developments that could reduce carbon footprint of extraction, the potential for a reorganization in the metal supply chain, and the possibility of closer relationships between society and the metals it utilizes.

Can we improve mining technology in order to reduce its carbon footprint? There is an active group of researchers who say yes. Here are some current avenues for investigation:

- Bacteria has been interfacing with minerals for over two billion years. They have decomposed the minerals and allowed the metals to dissolve in water. As a consequence, a Mineral microbiomehas developed that could be used for development Natural methods of extracting metalsTo dispose of mine waste.

Continue reading:

How engineered bacteria can clean up oilsands pollution, mining waste and other pollutants

-

Current global greenhouse gas emissions are about 10% from mining operations. If we attempt to meet metals demand using current methods, this percentage will rise. Some companies are implementing renewable energy systemsIn an effort to further reduce this level of emission.

-

There is more potential for autonomous systems, some electrified. One possibility is a swarm of small machines that behaves like an insect colony. This could allow targeted metal extraction with a much smaller footprint.

These are complex ideas that will take time for them to become fully realized. We believe that a reorganization and better connections between society as well as the metals it uses can quickly lead to sustainable metal supply. To make the mineral resources industry more transparent, visible, and accessible to everyone, the first step is to remove its wrappers.

Metal supply chains

Suppliers who provide different services are the links in the metal value chains.

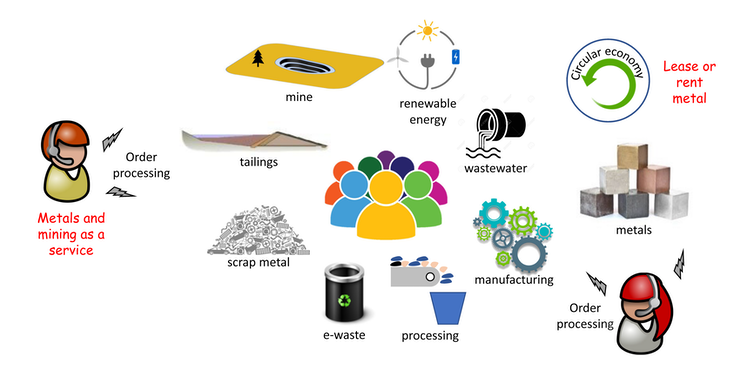

A mining company is a collection of suppliers. A network of multiple sources of metals, such as mines, scrap and electronic waste, can be an alternative. These metals are connected to processing plants and refineries, manufacturers, and related suppliers.

It is possible to have networks within networks. Flexibility is necessary. One network may specialize in the extraction of metals from tailings, while another might be focused on mineral concentrates. Another network may be solely concerned with recycling scrap metals. A company, group, community or individual could take ownership of and operate any part if they have the necessary knowledge and expertise.

(Authors)

Most of the innovation in mining comes from suppliersDifferent suppliers would be beneficial to each other in a network. Combining competition among suppliers to be part of a network and collaboration between suppliers in those networks would encourage innovation.

There are many ways for the public and others to get involved in an open metal supply network. While barriers to entry aren’t impossible, there are benefits to removing them.

Many mineral deposits in Canada are found on Indigenous lands. A mining company, or group of companies, could manage/finance a part of the network related to these minerals deposits.

THE CANADIAN PRESS/Ryan Remiorz

Many of the metals required for renewable energy systems are found in small deposits that are geographically dispersed. Rare earth metals used as magnets for electric cars’ motorsOne example is the mining of coal. These deposits are too costly to develop, but a flexible network that provides services only when needed might be possible.

It is difficult to separate metals

Recycling is another source of metals. However it is difficult to separate the metals contained in some products due to the combination of materials.

This requires some innovation in processing. However, recycling can be complicated, especially for heavy items like an aircraft engine, an electric vehicle, or a few thousand hard drives. A network of communities and logistics professionals working together with advanced recycling operations could provide a sustainable source for metals.

It is possible to reuse or refurbish devices that contain metals. The circular economy. It would be necessary to coordinate between manufacturers and device users. This can be achieved through an open network of partners.

If we want to use renewable energies to keep the atmosphere cool, then our relationship with mining and our current relationship to metals must change. These policies should be promoted by the government. Industry can also play a role in encouraging business partnerships, engagement with communities, and other interested parties.